Sampling Program

Even before a sampling program that will support detailed mine modeling begins, a site may have enough supporting data to be considered a mining prospect. The best explored Apollo sites are characterized well enough to be considered mining prospects, particularly Apollo 17 for LOX-to- LEO. Assumptions may be made about the nature of the resources at these sites, and feasibility studies can begin. Such feasibility studies are a common and powerful tool in the mining industry, but they indicate that the major work on the prospect has just begun.

As a mining site, even Apollo 17 does not have nearly enough information to support mining operations. Questions such as grade variability, minable depth variability, and distribution of grain size (particularly oversized material) must be answered before mine and mill design can begin in earnest. The tool to answer these questions is the sampling program and ore body model. The Apollo sites were not sampled for the purpose of mining but for scientific inquiry. While it seems likely that the Moon is a fairly homogeneous body, there are not enough data even to predict the necessary sampling interval to build an accurate ore body model. Since the lunar? samples cannot be adequately correlated with underlying bedrock, additional investigations will be required that can define the extent and thickness of the regolith to be mined.

Apollo 15 Astronaut Taking a Core Sample of the Lunar Regolith

Apollo astronauts collected most samples by picking them up with tongs, a scoop, or a rake and bagging them for return to Earth. All rock samples were found as fragments or boulders in the lunar regolith (rock ground up by meteoroid impacts). A few cores were obtained. The longest. approximately 3 meters in length, were collected using a power drill. This one was obtained with a drive tube which was pushed or hammered into the regolith. Effective sampling for lunar resources will require more sophisticated drilling devices.

Mine and mill operations must be designed to handle such variables as soil mineralization, grain size, and mining depth. For example, constant feed simplifies mill operation, making it more efficient. Oversized material must be rejected, preferably in the mining, operation before it reaches the mill,. The many factors affecting operations must be determined and characterized. Since the scale of these soil variables is unknown, the sample interval itself must be determined before the program is implemented. For terrestrial mines, the cost of sampling is usually much lower than the cost of unexpected operational problems caused by failure to sample adequately. On the Mqon even the best explored sites have far too little data to support operations. Thus, the quality of the lunar sampling program will directly reduce operational problems.

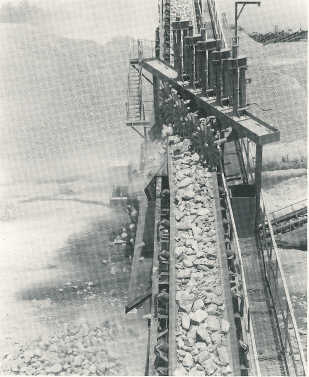

Rejection of Oversized Material

A number of methods exist for sorting larger rocks and boulders from mined

material. the device shown here (Side-Kick by General Industries, Inc., Marietta,

GA) automatically removes the larger rocks from a conveyor belt and collects

them in a stockpile. The motion of the conveyor belt forces the rocks into several

spoked wheels, placed at a predetermined angle to and a preset level above the

oncoming conveyed materials. The rocks spin these wheels, causing the spokes

of the wheels to kick these rocks over the side of the belt. Thus, the device

works much like a diverting waterwheel in a stream. The kicked out rocks can

be collected in a pile or a bin. A lunar version of this device could provide

a selection of different sizes of rocks for use as paving and building stones

as well as eliminating the larger rocks from the feedstock to

be processed for oxygen or hydrogen.